A few weeks ago my Apple Airport Time Capsule up and died. The little green light went out and it just stopped working. For anyone who doesn’t know what an Airport Time Capsule” is it is a combination wi-fi router and wireless backup device. So when it went dead, I lost wi-fi in the house. Anyway, I was tempted to buy a new one at $300 a pop, but then I did a little research. Turns out these things have had a bad track record of going belly up, and the culprit generally is the power supply cooking itself to death, mainly because these devices don’t have adequate cooling. The components get overheated and over time you eventually have a failure. So I rolled the dice and spent $15 on a “repair kit” on eBay to fix it. We had a secondary wireless router that I was able to press into service in the meantime not making it a crisis at home.

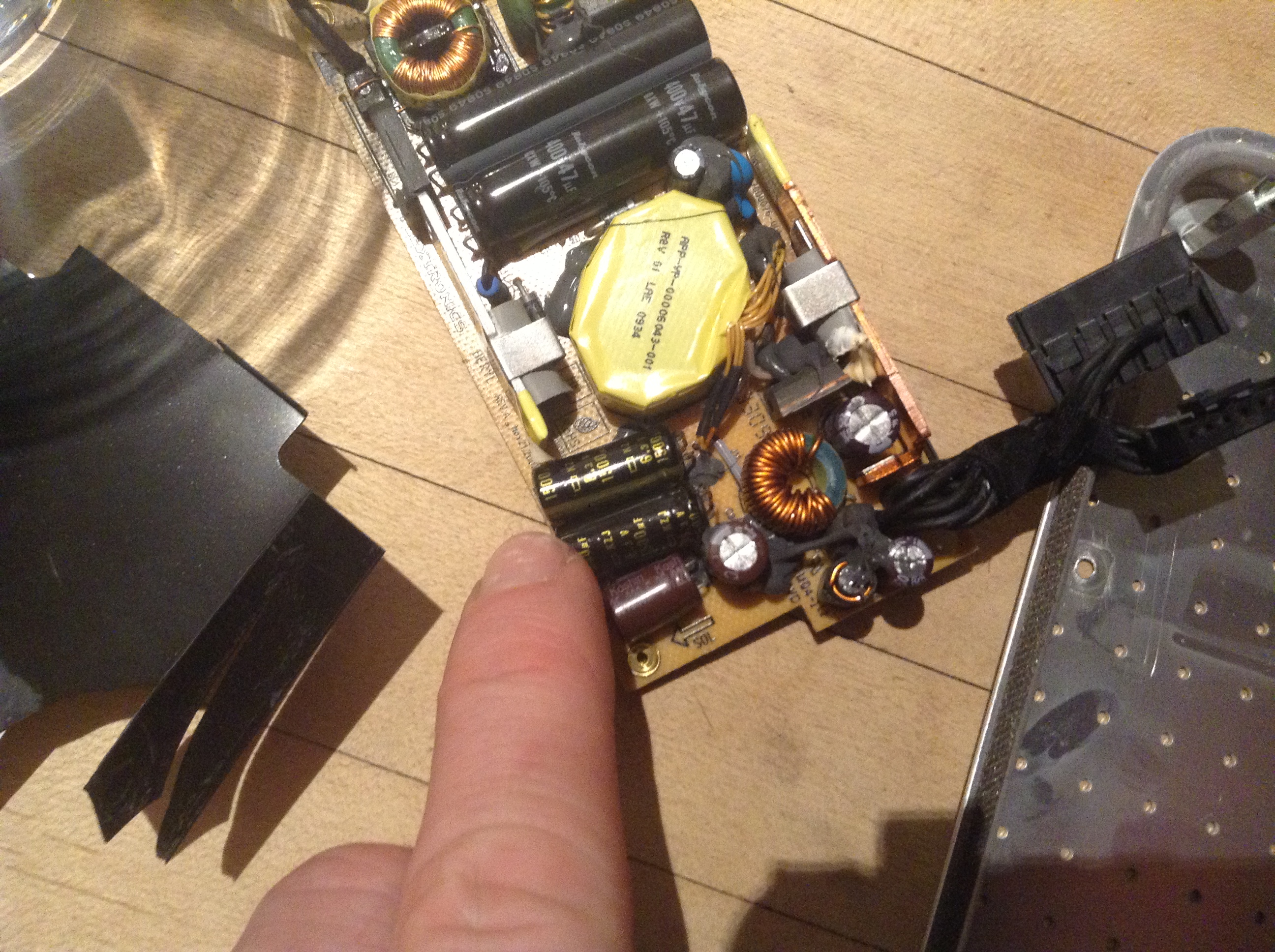

A few days later the repair kit came in the mail – consisting of $5 in capacitors and instructions on how to effect the repair yourself. I could have researched the components myself but this seemed a fair price for the intellectual property on how to do it yourself. I had failed to realize when I bought the kit how much in the guts I had to get to fix it. This was no plug and play repair, I had to open up the power supply and re-solder new capacitors to the motherboard. No matter. I was game.

Sure enough after following all the directions (Do not try this without following someone’s directions, or at the very least let it sit unplugged for several days or manually discharge the capacitors so you don’t kill yourself) I found the offending capacitors. There were 4 in the replacement kit, but since my soldering skills are lackluster I opted for just replacing the ones that were clearly bulging and failed, which in this case meant the pair at the bottom of the board. I now recommend anyone doing this to just replace all four capacitors. The other two are easy to replace and even if they haven’t failed yet, I guarantee they are out of spec. But more on that later.

After some cursing I managed to get the old ones removed and new ones installed. I carefully put the whole thing back together, went upstairs, plugged it in, and all the Ethernet cables, and after a minute the light went from amber to green and lo and behold the system was back up and running.

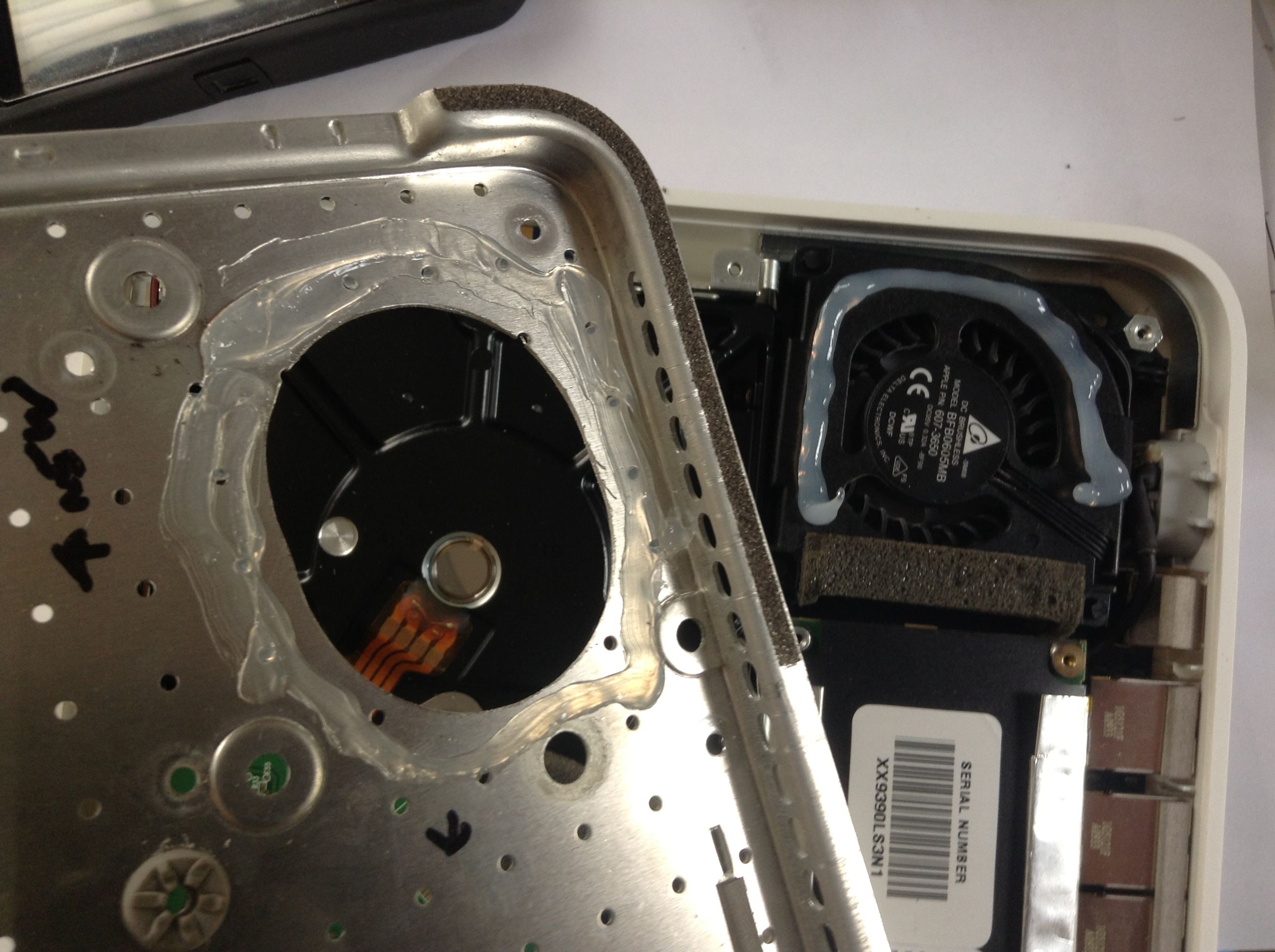

Also, now that I had the system cracked open it was a simple matter to pull the existing 1TB drive in there and replace it with a 2TB drive. Literally unplug two cables and peel off heat sensor attached with adhesive. The drive itself is not secured in any way. It just has nowhere to go, and I guess Apple assumes these things aren’t going to be moved around a lot while running. There was a Western Digital Black drive in there and I went with a new WD drive as well. You have three choices, a WD “green” drive which uses less power, “blue” drive which is for general computing, or “black” drive which is more “enterprise” class and will stand up to heavy use. It makes sense Apple would put a Black version in there. The thing is on 24/7 as it is also your wireless router, and the drive is not user serviceable. Or at least they discourage it. My feeling is that as this thing is really only a backup and not a NAS I don’t care too much if the drive goes bad in two years or something, by then drives will be even cheaper and I now know how to get in it, so replacing it is a minor inconvenience. So I went with Blue as a replacement. A very reasonable choice would have been Green, as the device has a known problem with heat dissipation a drive that conserves energy also conserves heat. Also, any performance loss from a Green drive not spinning as fast is going to be invisible due to the bottleneck of wi-fi anyway. I didn’t put in Green because it cost $10 more and I am a cheap skate.

So now I have a new drive in the Time Capsule and a functioning power supply. Time to put it all back together. I plug everything back together and then screw the aluminum bottom back on. Now, I didn’t explain how I opened the Time Capsule so I will review the first steps to get in. You get in from the bottom. The big featureless rubbery bottom that keeps it from sliding on whatever it sits on is glued directly to this aluminum base. With a good hair dryer or heat gun you can peel back (slowly!) the whole rubbery foot, revealing this cheese plate aluminum base with a bunch of small screws recessed it it that holds the aluminum base to the rest of the unit. So, here I am putting this thing together, thinking that all I did was fix the symptoms, not the cause. What is to prevent this thing from overheating in a year or two and me going back in to re-solder new components in? I really don’t want to put this suffocating rubber mat on top of this nice thin aluminum heat sink with a bunch of ventilation holes on it. And since heat rises, I decide to just put the aluminum base on, and then call it the top and put the Time Capsule upside down so the aluminum can dissipate heat off the top of the unit. A bit ugly, but hey it works.

Apparently the rubber base is “Thermal Rubber” or something and unlike regular rubber which is an insulator, this rubber does conduct heat. Or at least that is Apple’s claim. Even so, it can’t be as good as aluminum with a bunch of holes in it.

Further Mods:

After feeling pretty smug, I do a little research on other people’s solutions for cooling. Well, turns out the Time Capsule is “double insulated” which is why the plug doesn’t need a grounding third pin. But one of the rules of double insulating is there can be no exposed metal that the user might touch. That way even if there is an electrical fault, if say, I don’t know, some guy decides to do a homemade repair on the power supply, nobody is going to get juiced touching the outside. At this point I have visions of one of my cats stepping on the damn thing and getting full current and at best, dead cat, and at worst, house burnt down. So I decide it is time to revisit my cooling technique.

After doing some research on other blogs I find that several people have been doing one of two things: removing the power supply entirely and putting a 3rd party external one in which fixes cooling by quite a lot, or by modifying the fan. I opted for the second choice.

If you are thinking of modding your time capsule, I strongly suggest you read these websites of guys who have done it before and from whom I learned a lot in prepping mine. Both of them either sell kits or will do the repair for you.

http://www.fackrell.me.uk/

https://sites.google.com/site/lapastenague/time-capsule-power-supply-repair-kits

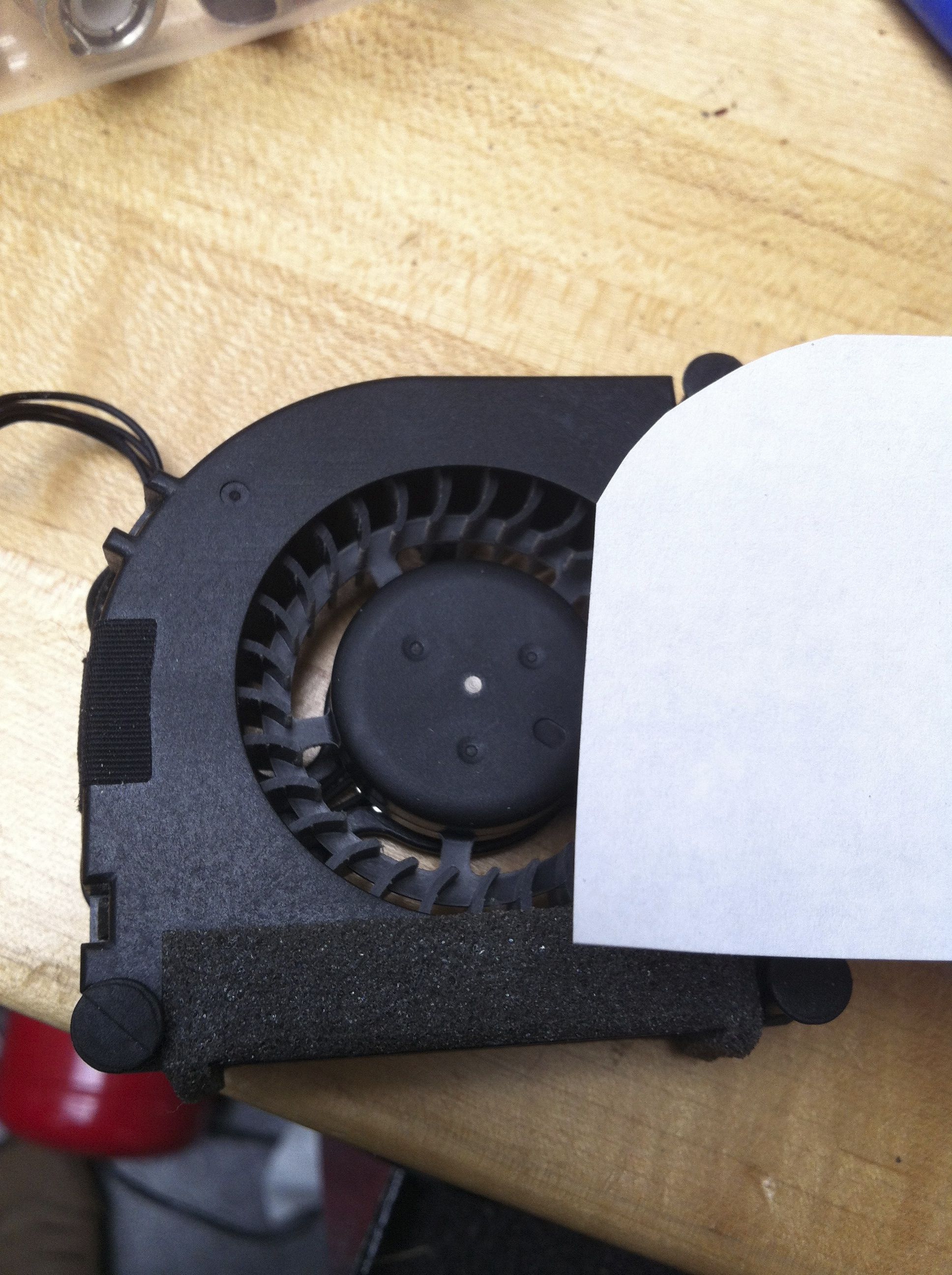

First, lets talk about the stock fan placement. It butts up directly to the hard drive. It appears to suck air up and then blow it to one side, that side is directly onto one portion of the hard drive. I am no engineer, but wouldn’t you want the fan to blow on the hottest component? Which in this case is the power supply, hands down. And unlike the hard drive which is fairly sealed, the power supply is insulated on 4 sides, with two ends open, sort of like an open-ended burrito, so you could easily blow air through it. You just need to rotate the fan 90 degrees to get it to blow in the right direction. But I guess it doesn’t really matter because the fan doesn’t even come on unless there is a near meltdown in the device. One possibility I didn’t fully explore is moving the temp sensor that is on the drive to the power supply, but that is mainly because I decided to follow the advice of other hackers that disable the MOBO control of the fan entirely and just manually make it spin at a low-level all the time. Again, more on that in a little bit. But first the fan mod.

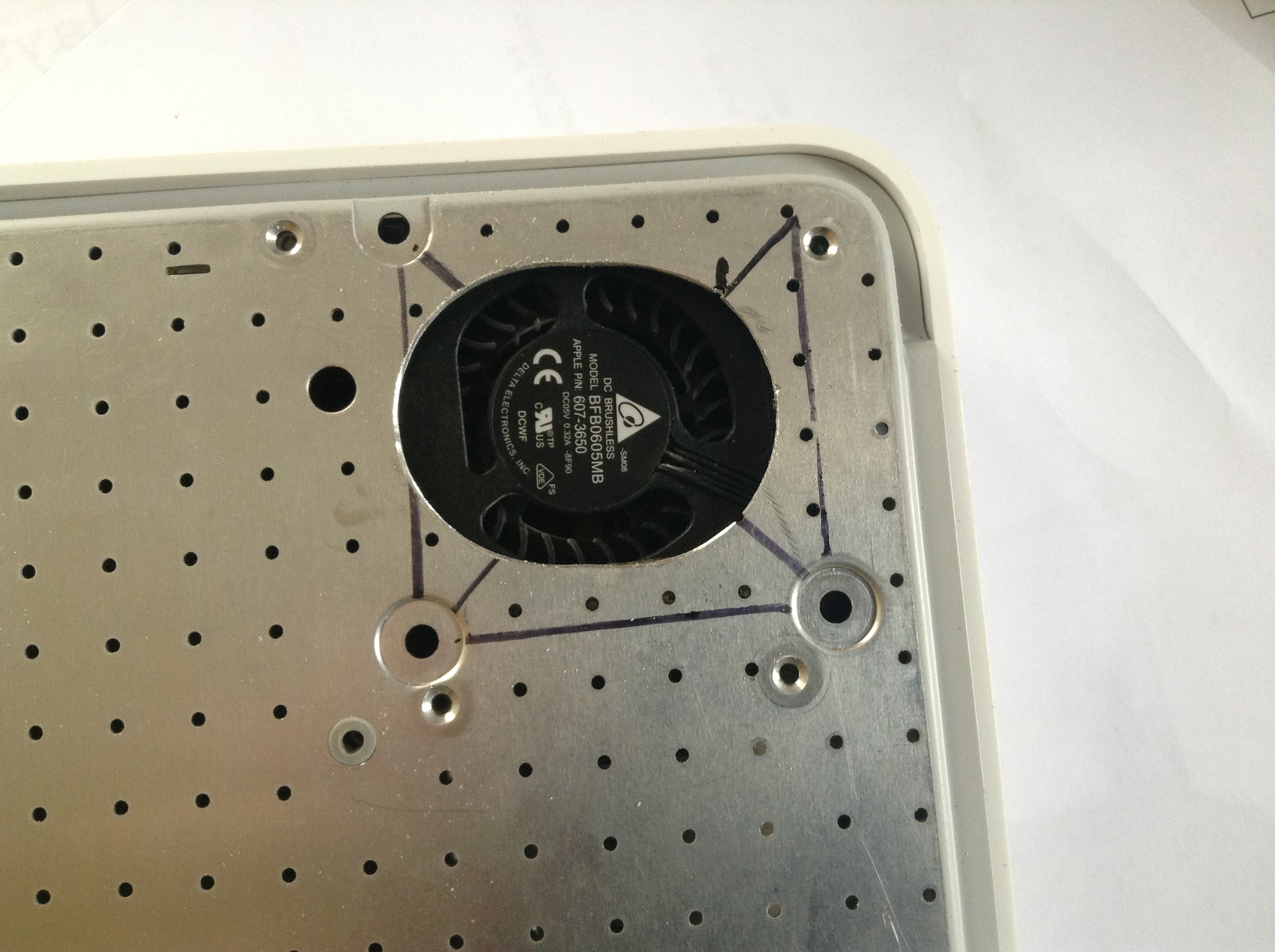

So, the plan is to rotate the fan 90 degrees. Turns out the best way to do this is to remove it from the aluminum bottom cheese plate and flip it over and THEN rotate it so the exhaust points to the power supply. This gets a little involved. First lets talk about the stock ventilation on the Time Capsule.

- New Fan Placement: Notice exhaust now facing to the right (again, where the foam is) and that the fan had been inverted with the text now facing us.

In standard Apple procedure there appears to be no ventilation whatsoever. This is not the case. The thin groove along the upper part of the side hides the upper ventilation ports. And if you look very carefully at your rubber foot along the edge there are some holes in the aluminum base along the edge that are open to the air. So, there IS ventilation, just very minimal, and mostly passive.

the ventilation of the Airport. The holes along the side are hidden but not plugged by the rubber base that is currently removed. The exhaust ports are hidden in the seam around the device, where the black screwdriver is pointing. Apple went through great pains to hide any visible cooling elements.

The fan only comes on in emergencies. And the fan has no direct access to any of the vents. It just cycles air around and I guess they hope convection moves hot air out the top and in from the bottom. So mostly passive. But since it is Apple I would call it more “passive aggressive” cooling.

Since the Time Capsule has failed once due to its heat load, its time to put the equivalent of a hood scoop on this thing and get that air moving. Flip the fan over, point it’s exhaust at the power supply, cover one of the intakes of the fan with a paper “plug” to force it to only use one side and cut a hole in the chassis of the Time Capsule so that the fan has access to the outside world. Plus the mod to make it spin all the time. All righty then.

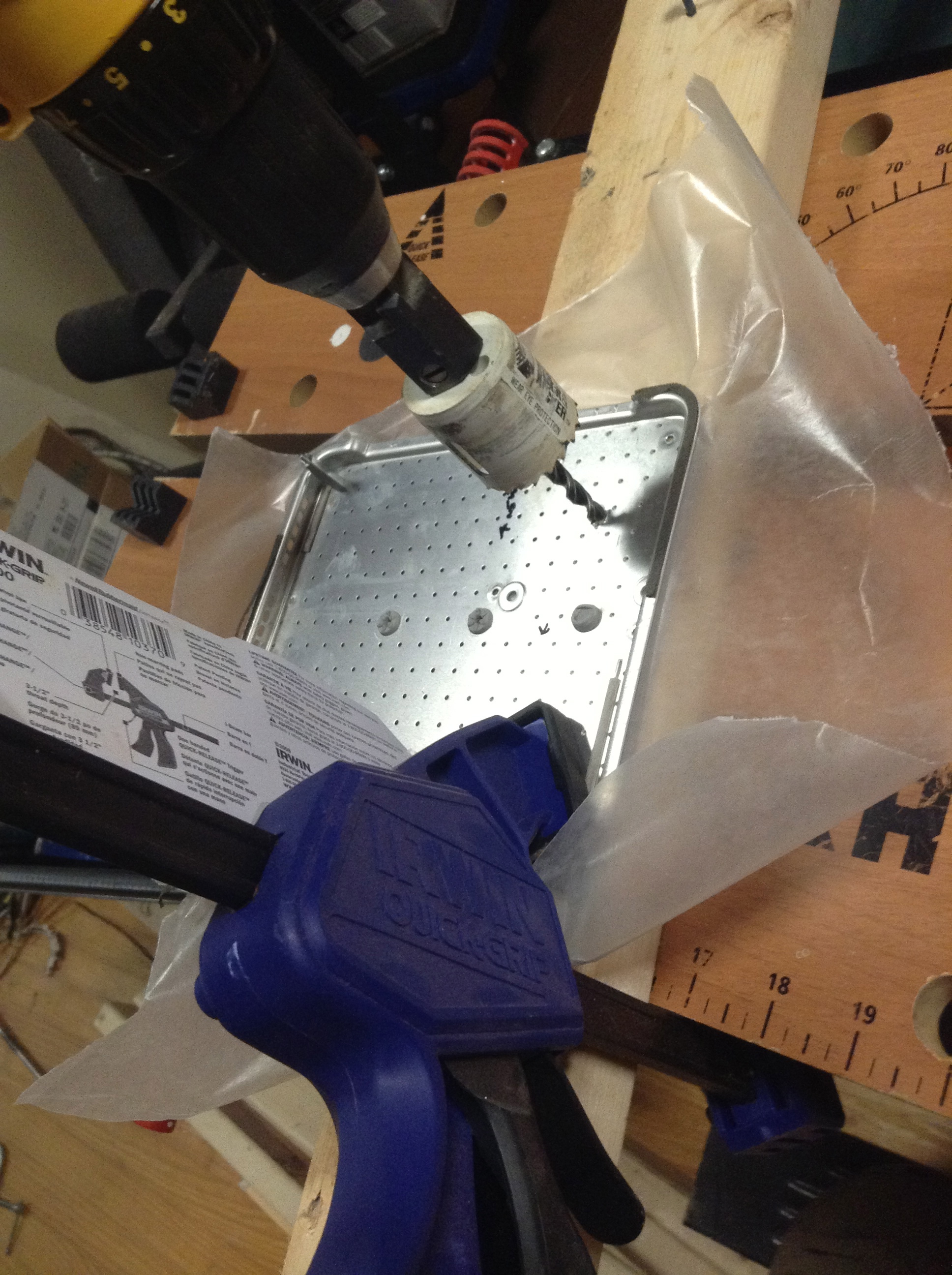

The fan is held by rubber insulator/ suspension “feet” to the aluminum cheese plate. Some people have suggested removing them, flipping them, removing 5mm from them and crazy-gluing them back together to make everything fit properly as the other side of the fan is a different thickness. Way to fiddly for my taste. I just flipped it, left the rubber feet on, which now contact a circuit board and keep the fan off that, and use silicone as the glue, insulator, vibration absorber all rolled into one to the aluminum cheese plate. This is so much easier. All I have to do is cut a hole in the chassis. I mark the center of the three points where the rubber feet go though the cheese plate, find a suitable hole saw (I was determined not to buy one for this job, so the hole was going to be “best available” size.) and start drilling.

I want a matching hole through the rubber base, but I don’t want a bunch of metal shavings stuck to the remaining adhesive on it so I put a layer of wax paper between the aluminum and rubber. I make a nice neat round hole which I file the edges so it is smooth. The hole through the rubber is pretty smooth too, and cleans up nicely. And the wax paper did a great job of keeping the metal shavings off of the glue.

I am feeling pretty proud of myself, and my neat round hole. I then dry fit the pieces together with the fan in the new position. Did I mention I didn’t measure twice, cut once? At this time I decide that perhaps oval would be an excellent shape after all, and drill an additional hole into the side of the existing hole so that the fan intake will actually line up with this new port I am making. Despite that setback, I am back on track.

Er, oval is just as good as round right? At least now the fan has a clear access to the outside world now.

Again, since I want the fan to draw from only the port I have just cut, I have to cover over the other side of the axial fan. Easiest way to do this would be with a bit of clear packing tape, but that would leave sticky bits facing inside that would eventually gather dust and disable the fan. So the best solution is to cut a template out of paper and then tape that to the side of the fan that will now face into the device.

So, so far I have the hole for the fan in the chassis, the fan’s intake adjusted. I now want to install the fan to the aluminum base, and mod its power control.

The fan has a 4 cable wire harness. Cut wires 2 and 4, and you have cut the wires that communicate from the MOBO to turn on and at what speed. If you only cut wire 2 the fan will run at 100% all the time, which will cool it quite well, it will be too loud. The other wire that controls the speed, you will cut and put a resistor in line to slow it. It seems different models of Time Capsules have different requirements, but I got a 33 ohm one which seems to work fine for me. Strip the wires, solder the resistor on and either use shrink wrap or in my case, electrical tape to insulate any exposed metal. Then plug the harness back in and place the fan in the new orientation into the Time Capsule.

One last step before putting it all together. For style points, you don’t want the fan guts directly accessible via the new hole you cut, even if it is going to be the underside of the unit. I took a piece of screen from an old screen window and cut it to size and ran a bead of caulk around the inside of the opening and gently press it in. I then run a fatten bit of caulk around the fan chassis where I think it will come in contact with the aluminum base and just a bit more on top of the screen edges.

Then press the aluminum base on and screw it down. I left the unit off for 12 hours so the silicone can set up and dry. This is also a good time to buy some self adhesive rubber feet and put these on the base. That way the unit will sit a little higher off the ground and let the fan intake easier access to airflow.

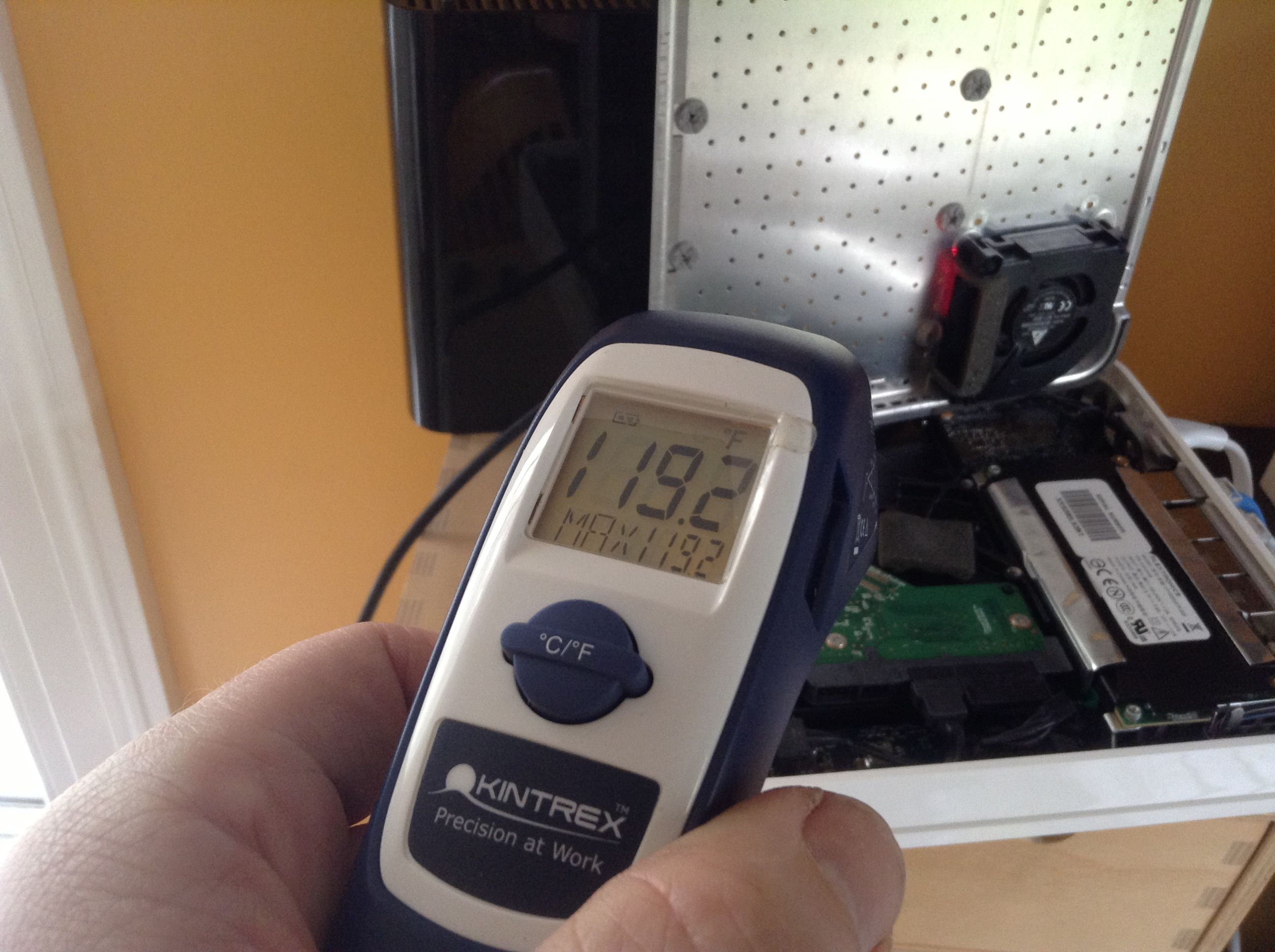

I did several thermal tests during different stages of my reconstruction. With the power supply back up and running and the unit right side up I got readings close to 120 degrees F on the top above the power supply. And more than 20 degrees lower on the top above the hard drive side.

I did do a test with the fan running at 100% before I cut the speed control wire and I can confirm it is too loud. With the resistor in place the fan is much quieter. If the windows are open to normal summer bug and bird sounds it is inaudible. If the windows are shut, you can hear it faintly. So if you wish to have an even quieter fan you could explore different resistors.

And one last note. You know how I recommend you replace all the capacitors while you have the thing open? While mine was back up and running, it still had a problem where it would run for a week to ten days and then power off. Re-patching the power plug rebooted it. But 10 days later same thing. I figured it was the two remaining capacitors. So I had to crack it open again, open up the power supply again, discharge the high power capacitors, and swap out the remaining parts I had and re-assemble. It has worked like a champ since then. Although you can now hear a faint whirr when the room is quiet. I can live with that.